Tool Grinding Machine

-

Hot

Diamond Grinding Wheel

Diamond wheels are different in structure from ordinary abrasive wheels, and generally consist of a diamond abrasive layer, a transition layer and a matrix. Diamond wheels are super-hard abrasive wheels. Compared with ordinary abrasive wheels, diamond wheels have very obvious characteristics and advantages. According to the bonding agent, diamond grinding wheels can be divided into: resin bonding diamond grinding wheels; ceramic bonding diamond grinding wheels; metal bonding diamond grinding wheels (bronze bonding diamond grinding wheels). Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels become an ideal tool for the grinding and processing of hard and brittle materials such as glass, ceramics, gems, stone and hard alloys.

Email Details -

Hot

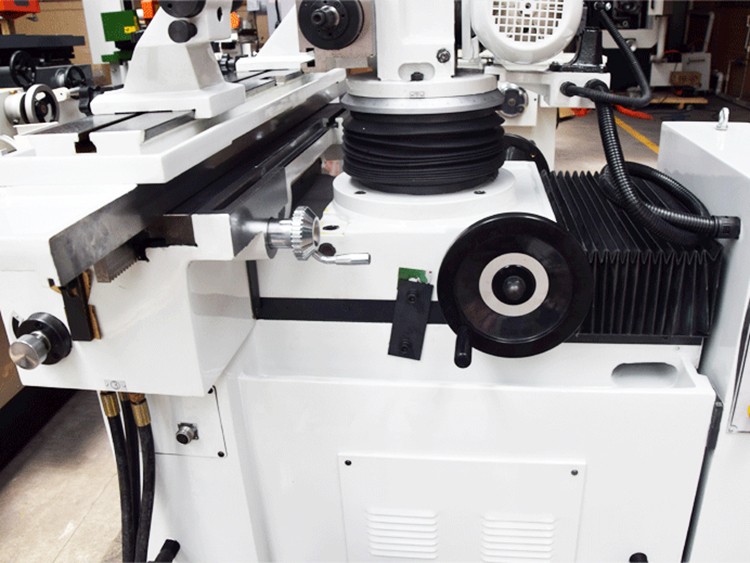

Cnc Diamond Tools Grinding Machine

artificial diamond (PCD) tool grinder is a device used to manufacture and repair PCD tools, PCBN tools and single crystal tools. Its feed shaft is equipped with a screw rod, which is safe and reliable in operation. High cutting efficiency, dual operation station design, high cost performance. Pneumatic device can fast forward and rewind to improve production efficiency. Flexible feed and constant pressure grinding ensure the quality of the cutting edge of the tool. It can grind standard or non-standard turning and milling inserts. Boring, slotting and many other types of tools can also easily grind angles and radii on this machine

Email Details

machine characteristics:

1. Machine tool structure: The machine bed (base) is made of high-quality integral castings, and the main components weigh 1.6 tons, which can meet the requirements of any superhard material grinding. The rotary axis of the tool has high precision and rigidity, and the air brake device is adopted, which greatly improves the work efficiency.

2. Electric spindle of machine tool: The grinding head adopts high-precision variable frequency speed-regulating electric spindle, power: 3.0 kW, maximum speed can reach 4000 rpm, and it is cooled by circulating water. The main shaft adopts high-precision long-life bearings, and the grinding head's main shaft rotation accuracy is 0.002 mm for end jump and 0.003 mm for runout.

3. Manual feed mechanism: The machine tool adopts two methods of "rapid feed" and "precision feed", which are used for rapid feed / retract (0.5 mm / rev) and working feed (3 mm / rev) It not only improves the production efficiency but also guarantees the feeding accuracy.

4. Grinding head swing: The electrical swing controlled by intelligent components is stable and has no reverse vibration. The swing amplitude can be adjusted freely between 0 and 30 mm, so that the grinding wheel is consumed uniformly and sharpened in time. The swing guide adopts the holder of SCHNEEBERG in Switzerland, which effectively guarantees the grinding accuracy and roughness. -

Hot

Cnc Tool Grinding Machine For Pcd Tools

The tool grinding machine has high precision, good rigidity, and is economical and practical. It is especially suitable for sharpening various small and medium-sized tools, such as reamers, taps, twist drills, reaming drills, various milling cutters, milling cutter heads, and gear shapers. With the corresponding accessories, it can grind the outer circle, inner circle and plane, and can also grind samples and molds. Diamond wheels can be used to sharpen a variety of carbide tools.

Email Details

The universal tool grinder is an improved tool grinder with excellent performance. After attaching accessories, it can grind the outer circle, the inner screen surface, and the template in addition to the common tools and various special tools such as sharpening cutters, milling cutters, inclined groove hobs, broach cutters, and gear cutters. The processing range is relatively wide. -

Hot

Tool Grinding Machine

The tool grinding machine has high precision, good rigidity, and is economical and practical. It is especially suitable for sharpening various small and medium-sized tools, such as reamers, taps, twist drills, reaming drills, various milling cutters, milling cutter heads, and gear shapers. With the corresponding accessories, it can grind the outer circle, inner circle and plane, and can also grind samples and molds. Diamond wheels can be used to sharpen a variety of carbide tools.

Email Details

The universal tool grinder is an improved tool grinder with excellent performance. After attaching accessories, it can grind the outer circle, the inner screen surface, and the template in addition to the common tools and various special tools such as sharpening cutters, milling cutters, inclined groove hobs, broach cutters, and gear cutters. The processing range is relatively wide.

-

Hot

Notching Insert Tool Sharpner

The tool grinding machine has high precision, good rigidity, and is economical and practical. It is especially suitable for sharpening various small and medium-sized tools, such as reamers, taps, twist drills, reaming drills, various milling cutters, milling cutter heads, and gear shapers. With the corresponding accessories, it can grind the outer circle, inner circle and plane, and can also grind samples and molds. Diamond wheels can be used to sharpen a variety of carbide tools.

Email Details

The universal tool grinder is an improved tool grinder with excellent performance. After attaching accessories, it can grind the outer circle, the inner screen surface, and the template in addition to the common tools and various special tools such as sharpening cutters, milling cutters, inclined groove hobs, broach cutters, and gear cutters. The processing range is relatively wide.