Cheap Diamond Grinding Wheel wholesale quotes

- LUCUBRATE

- CHINA

- 30DAYS

- 200PCS PER YEAR

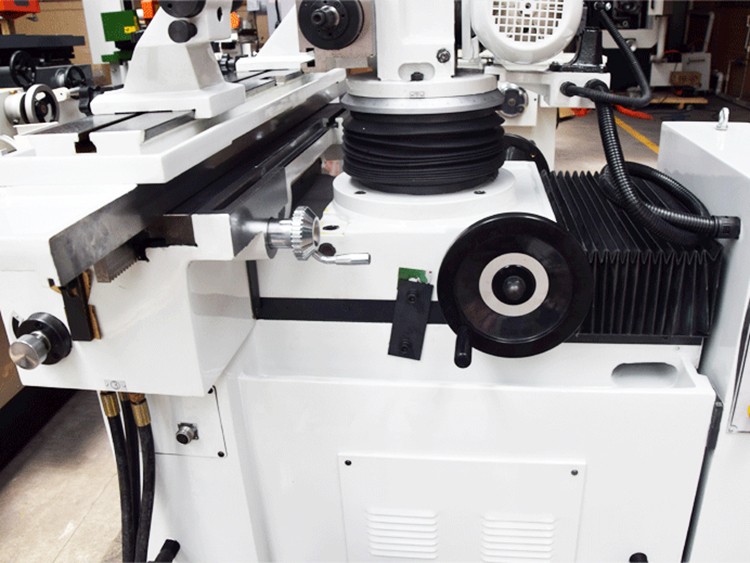

Diamond wheels are different in structure from ordinary abrasive wheels, and generally consist of a diamond abrasive layer, a transition layer and a matrix. Diamond wheels are super-hard abrasive wheels. Compared with ordinary abrasive wheels, diamond wheels have very obvious characteristics and advantages. According to the bonding agent, diamond grinding wheels can be divided into: resin bonding diamond grinding wheels; ceramic bonding diamond grinding wheels; metal bonding diamond grinding wheels (bronze bonding diamond grinding wheels). Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels become an ideal tool for the grinding and processing of hard and brittle materials such as glass, ceramics, gems, stone and hard alloys.

Diamond wheels are different in structure from ordinary abrasive wheels, and generally consist of a diamond abrasive layer, a transition layer and a matrix. Diamond wheels are super-hard abrasive wheels. Compared with ordinary abrasive wheels, diamond wheels have very obvious characteristics and advantages. According to the bonding agent, diamond grinding wheels can be divided into: resin bonding diamond grinding wheels; ceramic bonding diamond grinding wheels; metal bonding diamond grinding wheels (bronze bonding diamond grinding wheels). Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels become an ideal tool for the grinding and processing of hard and brittle materials such as glass, ceramics, gems, stone and hard alloys.

Diamond wheels are super-hard abrasive wheels. Compared with ordinary abrasive wheels, diamond wheels have very obvious characteristics and advantages:

1. The hardness of the diamond abrasive determines the main characteristics of the diamond grinding wheel. It can efficiently grind hard-to-machine materials such as hard alloys, glass and ceramics, and the grinding tools have the longest service life.

2. Diamond has high abrasion resistance, less wear of the grinding wheel, and longer use time. In the grinding process, the size, shape and morphology of diamond abrasive grains change little, which is more suitable for high precision processing and production High efficiency, diamond grinding wheel is a tool that can meet both high efficiency and precision machining.

3. The sharpened diamond wheel can maintain the micro-edge of the abrasive particles for a long time, and the good cutting performance ensures a small grinding force during the grinding process, thereby reducing the grinding power and saving energy.

4. The thermal conductivity of diamond is very good, which is conducive to the evacuation of heat, avoiding the phenomenon of workpiece burns, cracks, and block dropping, which greatly improves the quality of surface processing of workpieces.