China Cnc Diamond Tools Grinding Machine wholesale customized

- LUCUBRATE

- CHINA

- 30DAYS

- 200PCS PER YEAR

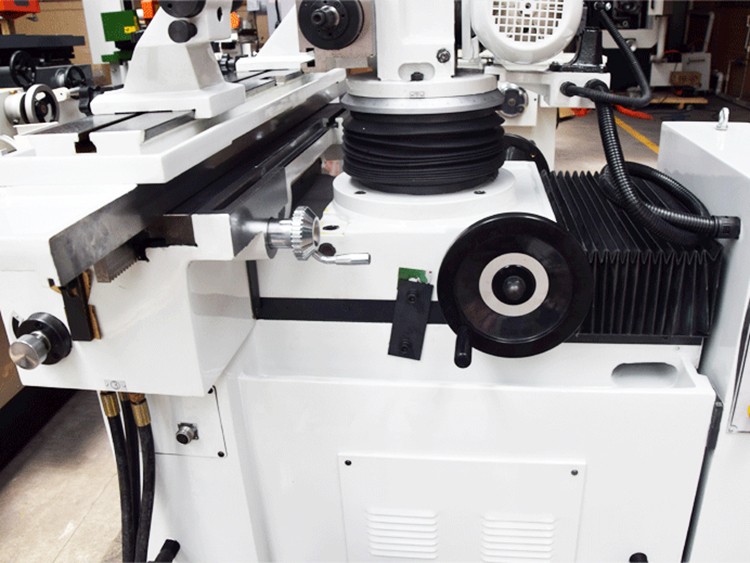

artificial diamond (PCD) tool grinder is a device used to manufacture and repair PCD tools, PCBN tools and single crystal tools. Its feed shaft is equipped with a screw rod, which is safe and reliable in operation. High cutting efficiency, dual operation station design, high cost performance. Pneumatic device can fast forward and rewind to improve production efficiency. Flexible feed and constant pressure grinding ensure the quality of the cutting edge of the tool. It can grind standard or non-standard turning and milling inserts. Boring, slotting and many other types of tools can also easily grind angles and radii on this machine

machine characteristics:

1. Machine tool structure: The machine bed (base) is made of high-quality integral castings, and the main components weigh 1.6 tons, which can meet the requirements of any superhard material grinding. The rotary axis of the tool has high precision and rigidity, and the air brake device is adopted, which greatly improves the work efficiency.

2. Electric spindle of machine tool: The grinding head adopts high-precision variable frequency speed-regulating electric spindle, power: 3.0 kW, maximum speed can reach 4000 rpm, and it is cooled by circulating water. The main shaft adopts high-precision long-life bearings, and the grinding head's main shaft rotation accuracy is 0.002 mm for end jump and 0.003 mm for runout.

3. Manual feed mechanism: The machine tool adopts two methods of "rapid feed" and "precision feed", which are used for rapid feed / retract (0.5 mm / rev) and working feed (3 mm / rev) It not only improves the production efficiency but also guarantees the feeding accuracy.

4. Grinding head swing: The electrical swing controlled by intelligent components is stable and has no reverse vibration. The swing amplitude can be adjusted freely between 0 and 30 mm, so that the grinding wheel is consumed uniformly and sharpened in time. The swing guide adopts the holder of SCHNEEBERG in Switzerland, which effectively guarantees the grinding accuracy and roughness.

artificial diamond (PCD) tool grinder is a device used to manufacture and repair PCD tools, PCBN tools and single crystal tools. Its feed shaft is equipped with a screw rod, which is safe and reliable in operation. High cutting efficiency, dual operation station design, high cost performance. Pneumatic device can fast forward and rewind to improve production efficiency. Flexible feed and constant pressure grinding ensure the quality of the cutting edge of the tool. It can grind standard or non-standard turning and milling inserts. Boring, slotting and many other types of tools can also easily grind angles and radii on this machine

machine characteristics:

1. Machine tool structure: The machine bed (base) is made of high-quality integral castings, and the main components weigh 1.6 tons, which can meet the requirements of any superhard material grinding. The rotary axis of the tool has high precision and rigidity, and the air brake device is adopted, which greatly improves the work efficiency.

2. Electric spindle of machine tool: The grinding head adopts high-precision variable frequency speed-regulating electric spindle, power: 3.0 kW, maximum speed can reach 4000 rpm, and it is cooled by circulating water. The main shaft adopts high-precision long-life bearings, and the grinding head's main shaft rotation accuracy is 0.002 mm for end jump and 0.003 mm for runout.

3. Manual feed mechanism: The machine tool adopts two methods of "rapid feed" and "precision feed", which are used for rapid feed / retract (0.5 mm / rev) and working feed (3 mm / rev) It not only improves the production efficiency but also guarantees the feeding accuracy.

4. Grinding head swing: The electrical swing controlled by intelligent components is stable and has no reverse vibration. The swing amplitude can be adjusted freely between 0 and 30 mm, so that the grinding wheel is consumed uniformly and sharpened in time. The swing guide adopts the holder of SCHNEEBERG in Switzerland, which effectively guarantees the grinding accuracy and roughness.

5. On-line CCD measurement: The tool setting and measuring system composed of optical microscope, CCD camera and industrial monitor are used to make the machine tool accurately detect various arcs from R0.05 to R20, and also to measure accurately Grooving knife width and angle of the tip. The three adjustment shafts of the CCD system support are driven by a backlash-free lead screw. The adjustment feel is good and the accuracy is maintained.

6. Radial locking of the grinding wheel shaft: The radial locking technology of the grinding wheel spindle enables the two arc guides to be locked in a concave and convex manner, achieving smooth contact without gaps, and greatly enhancing the rigidity of the equipment. The adjustment of the grinding wheel elevation angle (determining the tool back angle) does not change the position of the grinding wheel centerline, so coarse and fine grinding does not need to adjust the height of the grinding wheel.

technological breakthroughs

1. Double-station design: It can be conveniently operated and observed at the two stations of the machine tool. The positive station (axial direction of the grinding wheel) can avoid water splashing; the side station facilitates the grinding of special cutters such as cutters and partial cutters.

2. Optimization of vertical axis: The vertical axis lifting with minor adjustment is integrated on the fixture of the workbench, which greatly enhances the stability and rigidity of the equipment.