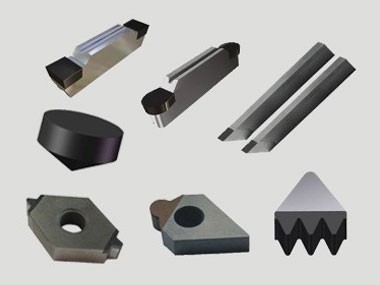

China Pcd Notching Inserts wholesale customized

- LUCUBRATE

- CHINA

- 30 DAYS

- 200000PER MONTH

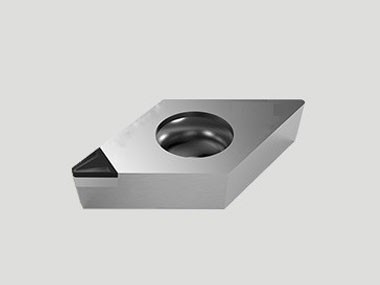

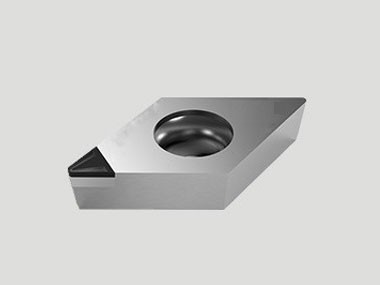

Advantage

Effectively solve the problem of constant chipping, and greatly improve the operating efficiency;

High-strength materials are used to achieve stable processing and long life;

Achieve superior chipbreaking in semi-finishing of aluminum alloys.

Application area

Industries: Automotive, 3C, Aerospace, etc .;

Material: aluminum, aluminum alloy, magnesium aluminum alloy, carbon fiber composite material, glass fiber composite material, etc.

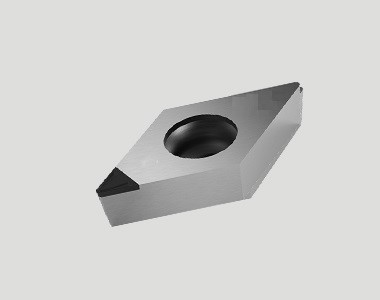

Advantage

Effectively solve the problem of constant chipping, and greatly improve the operating efficiency;

High-strength materials are used to achieve stable processing and long life;

Achieve superior chipbreaking in semi-finishing of aluminum alloys.

Application area

Industries: Automotive, 3C, Aerospace, etc .;

Material: aluminum, aluminum alloy, magnesium aluminum alloy, carbon fiber composite material, glass fiber composite material, etc.

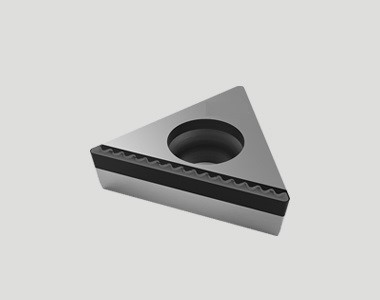

characteristic

CDW850

(CDW20-1)

Ultra-fine grain structure with strong edge sharpness and edge durability

Ultra-high-precision machining and high-mirror machining are suitable for milling and rough cutting of aluminum alloys with extremely high chipping requirements. They are mainly used for machining titanium alloys and composite materials.

CDW002

Higher cobalt content, good electro-machining performance, toughness and surface finish of the machined workpiece, which facilitates the processing of severely complex tools

It is mainly used in the machining of forming milling cutters and thread cutting tools. It can also be used in wear-resistant parts. It is used in the processing of wood chipboard, saw blades, silicon aluminum alloys, and power tool saw blades.

CDW010

Universal PCD grade, taking into account good toughness and high wear resistance

It is suitable for rough and fine cutting with a single tool, especially suitable for woodworking, low and medium silicon aluminum alloy parts.

CDW025

Extremely high abrasion resistance and cutting edge quality

It is more suitable for processing high-silicon aluminum alloys, metal matrix composites (MMC), hard alloys and ceramics, graphite and other brittle and hard materials. It is suitable for woodworking finishing knives, wear-resistant parts, woodworking calcium sulfate, saw blades, etc.