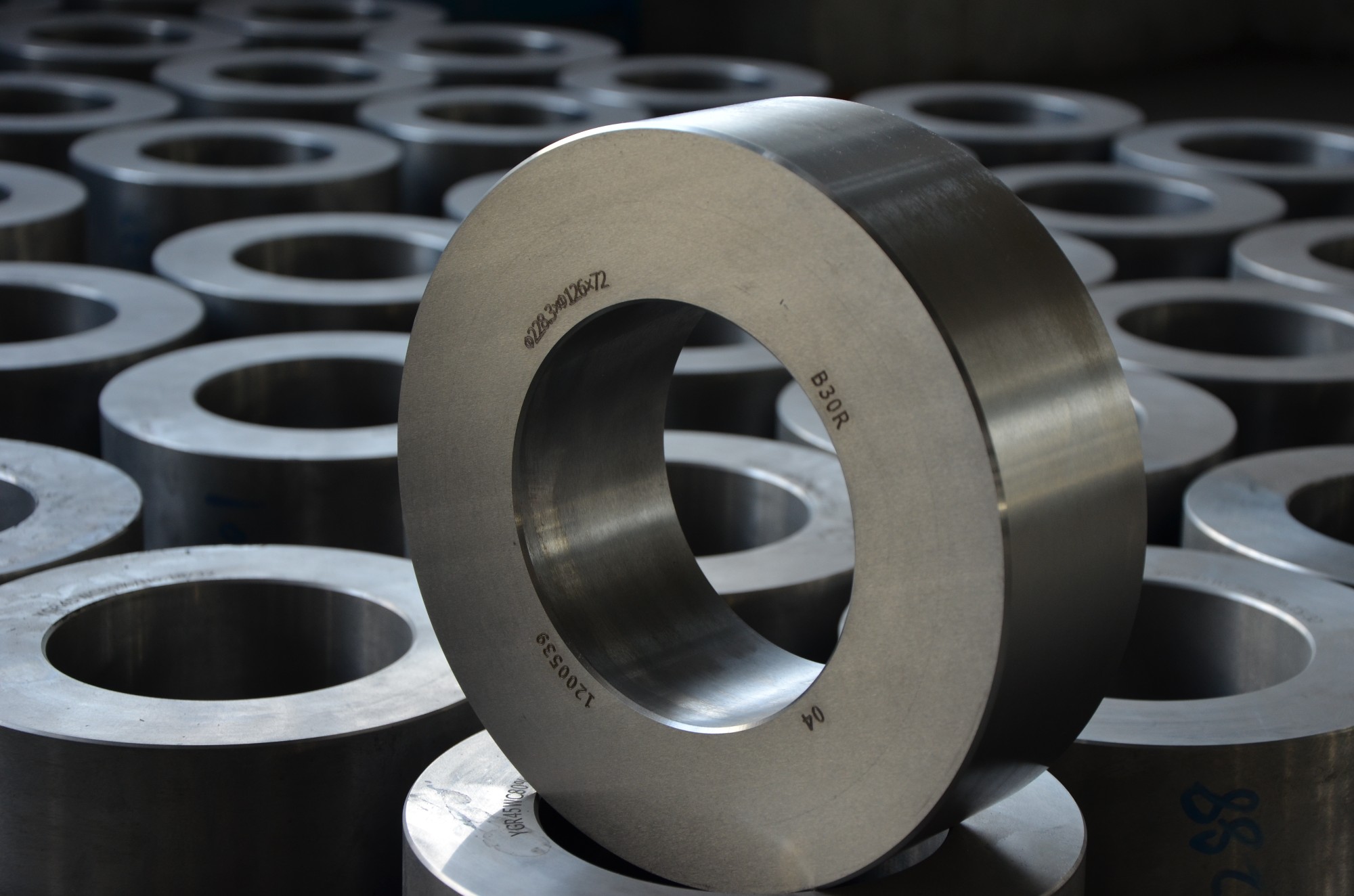

China High Speed Steel Rolls wholesale supplier

- LUCUBRATE

- CHINA

- 30DAYS

- 200PCS PER YEAR

Material characteristics

High-performance high-speed steel roll ring material: The high-performance high-speed steel roll ring is a steel-based roll ring that implements the national cast steel roll standard GB / T1503-2008. Its main alloy components are vanadium, nickel, tungsten, molybdenum, niobium, cobalt and other elements. , The carbon content is less than 1.6%, the phosphorus content must be controlled below 0.03%, the chromium content must be controlled below 5%, and the sulfur content must be controlled below 0.03%, so that the material's wear resistance and impact toughness are fully guaranteed At the same time, to ensure that the roller ring will not appear micro cracks, block loss, ring burst phenomenon in use. In particular, the tungsten content is strictly controlled, and segregation will not occur during centrifugal casting, so the hardness drop after each re-grinding is small, and the amount of steel passing will not decrease significantly.

◆ Manufacturing process

Process design review-tooling design-modeling-smelting-centrifugal casting-thermal insulation-unpacking-flaw detection-heat treatment after roughing-flaw detection-hardness testing-semi-finishing and corresponding testing-finishing and testing-metallographic inspection-factory inspection- wrap up and store.

All roll rings of our company are inspected 3 times one by one to ensure the inherent quality of the roll rings. All roll rings are tempered 3 times to obtain the best metallographic structure to ensure the best product performance.

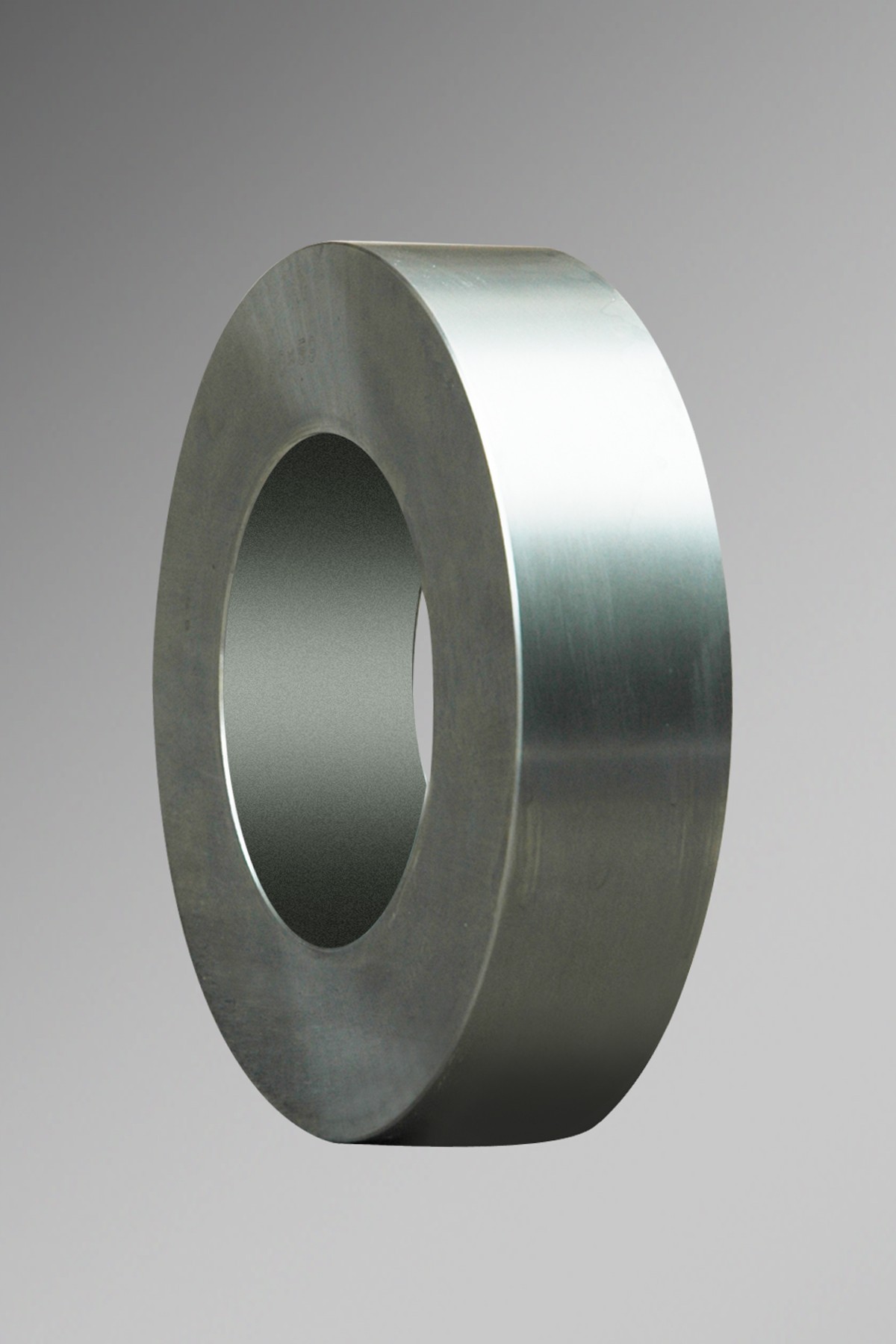

Material characteristics

High-performance high-speed steel roll ring material: The high-performance high-speed steel roll ring is a steel-based roll ring that implements the national cast steel roll standard GB / T1503-2008. Its main alloy components are vanadium, nickel, tungsten, molybdenum, niobium, cobalt and other elements. , The carbon content is less than 1.6%, the phosphorus content must be controlled below 0.03%, the chromium content must be controlled below 5%, and the sulfur content must be controlled below 0.03%, so that the material's wear resistance and impact toughness are fully guaranteed At the same time, to ensure that the roller ring will not appear micro cracks, block loss, ring burst phenomenon in use. In particular, the tungsten content is strictly controlled, and segregation will not occur during centrifugal casting, so the hardness drop after each re-grinding is small, and the amount of steel passing will not decrease significantly.

◆ Manufacturing process

Process design review-tooling design-modeling-smelting-centrifugal casting-thermal insulation-unpacking-flaw detection-heat treatment after roughing-flaw detection-hardness testing-semi-finishing and corresponding testing-finishing and testing-metallographic inspection-factory inspection- wrap up and store.

All roll rings of our company are inspected 3 times one by one to ensure the inherent quality of the roll rings. All roll rings are tempered 3 times to obtain the best metallographic structure to ensure the best product performance.

Design specifications and standards for manufacturing, quality control and inspection

The relevant standards of the roll ring are as follows:

The anti-rust packaging implements GB / T1504 and GB / T1503-2008 standards.

GB222 steel sample sampling method for chemical analysis and allowable deviation of chemical composition of finished product

GB223 steel and alloy chemical analysis method

GB / T13313 Roller Shore hardness test method

GB / T1804 General tolerances Tolerances for linear and angular dimensions without tolerances

GB / T1503-2008 National Standard for Cast Steel Rolls