China Vylindrical Engraving Machine customized quotes

- LUCUBRATE

- CHINA

- 30 DAYS

- 2000 PER YEAR

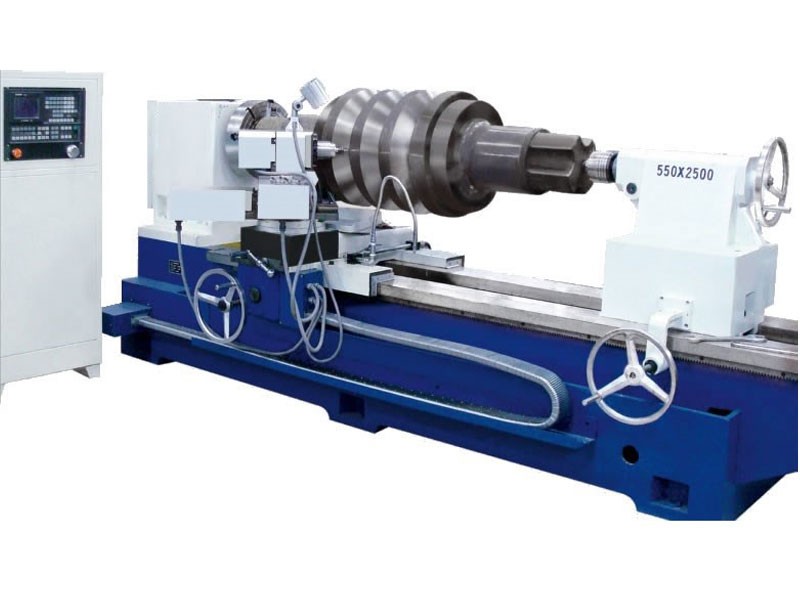

the main use of Roller Marker CNC Engraving and Milling Machine

Roller Marker CNC Engraving and Milling Machine (Angle Steel, Channel Steel Roller Marking and Milling Machine) It is suitable for marking engraving on the circumferential surface of small rolls and inclined surfaces less than 45 degrees. It can mainly be used for angled rolls and channel The bottom surface of the roll is processed for trademarks and marks. The machine tool has the advantages of high degree of systematization, easy adjustment, and specifications for marking and milling. Application of this machine can significantly improve work efficiency and reduce labor intensity.

the main parameters of the machine tool

1. Processing roll diameter: 250mm ~ Φ550mm

2. Processing roll length: 500mm ~ 2500mm

3. Axial angle between machining slope and workpiece: 0 ~ 45?

4, the minimum width of the processing bevel: 25mm

5. Rotating speed of engraving and milling spindle: 0 ~ 12000r / min

6. Engraving and milling spindle power: 2.2kw

7. Control system: GSK218M

8. Servo system rated torque: X axis 5NM

Y axis 10NM

Z axis 5NM

9. Power supply: 380V / 50HZ

10. Dimensions: 3900 × 1400 × 1550mm

11. Weight: 5000Kg

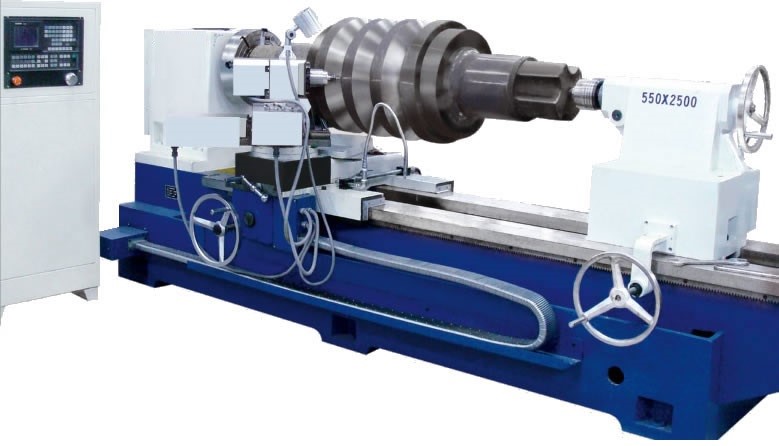

The main use of Roller Marker CNC Engraving and Milling Machine

Roller Marker CNC Engraving and Milling Machine (Angle Steel, Channel

Steel Roller Marking and Milling Machine) It is suitable for marking engraving

on the circumferential surface of small rolls and inclined surfaces less than

45 degrees. It can mainly be used for angled rolls and channel The bottom surface of the roll is processed for trademarks and marks. The machine tool has the advantages of high degree of systematization,

easy adjustment, and specifications for marking and milling. Application of this machine can significantly improve work efficiency and

reduce labor intensity

the main parameters of the machine tool

1. Processing roll diameter: 250mm ~ Φ550mm

2. Processing roll length: 500mm ~ 2500mm

3. Axial angle between machining slope and workpiece: 0 ~ 45?

4, the minimum width of the processing bevel: 25mm

5. Rotating speed of engraving and milling spindle: 0 ~ 12000r / min

6. Engraving and milling spindle power: 2.2kw

7. Control system: GSK218M

8. Servo system rated torque: X axis 5NM

Y axis 10NM

Z axis 5NM

9. Power supply: 380V / 50HZ

10. Dimensions: 3900 × 1400 × 1550mm

11. Weight: 5000Kg